Combined ballistic impacts pose a major challenge for engineers building structures that must withstand modern explosive threats

In an explosion, fragments and debris can be ejected at great speed and strike the surroundings. Then comes the shock wave. It’s a scary combination.

The combination of blast pressure and impact at high speed increases the chances of greater damage. PhD candidate at the Norwegian University of Science and Technology (NTNU), Benjamin Stavnar Elveli describes it as the scariest stress there is.

He said: “These combined impacts work in the same way as shrapnel bombs.”

In the past, protective structures have involved massive concrete military buildings. In recent decades, new threats have emerged, and the need to protect civilian buildings and structures in urban areas has increased.

This has fuelled interest in lighter, thin-walled solutions that can withstand large deformations without cracking and collapsing. The regulations have not followed this same development. No standards address this type of load yet, and research in the field is very limited.

Elveli has investigated how different types of thin steel plates behave when exposed to such extreme stressloads. His work can help to establish guidelines for how resistant, lightweight structures should be designed.

See also: Material fractures research could prevent damage to industrial parts

initial projectiles do the most damage

Whether they occur in accidents or on purpose, explosions can cause massive damage. Debris and fragments can be torn loose from parts of buildings, cars, gravel or stones. When they hit, they can act like projectiles.

Elveli says that any buildings, cars or other objects in the vicinity would be exposed to a load that is more serious than if either stressload occurred alone. The damage is believed to be greatest when fragments hit first.

He said: “That’s because the structure already has a defect or weakness from the projectile and then has to withstand the shock wave itself. Most often, cracking and destruction start in the weak spots.”

Elveli’s PhD is based on more than 80 small-scale explosion tests on three different types of steel. By combining physical experiments with theory and mathematical modelling, he has recreated the explosive loads in computer simulations.

The aim is to gain as much control as possible over how structures react to such loads, because the more scientists understand about the actual physics of these loads, the more accurate, safe and sustainable solutions the construction engineers of the future can deliver.

during the explosion

A shock wave can last for several milliseconds and cause great destruction over a large area. A fragment moves even faster and produces concentrated damage.

Simulating this combined effect means that you have to describe two completely different phenomena in one and the same model.

Elveli said: “Often you’ll end up with some sort of trade-off. In order to capture the local weaknesses that occur during the explosion, we need to determine how accurate the descriptions of the impact of the fragments should be.

“If we don’t achieve full control of this, the model could overestimate the strength of the building to withstand the stress.”

Overestimating strength can have fatal consequences. The solutions that construction engineers deliver have to be dependable. A large part of Elveli’s doctoral work has been to investigate how accurate the models need to be to ensure reliable buildings.

A common approach has been to assume that the fragments hit before the shock wave happens. The physical experiments then have to be divided into two different sequences that follow each other.

Often such studies use a simplified approach, where the test pieces have holes milled out by machine to mimic damage from real fragments.

overestimating resistance

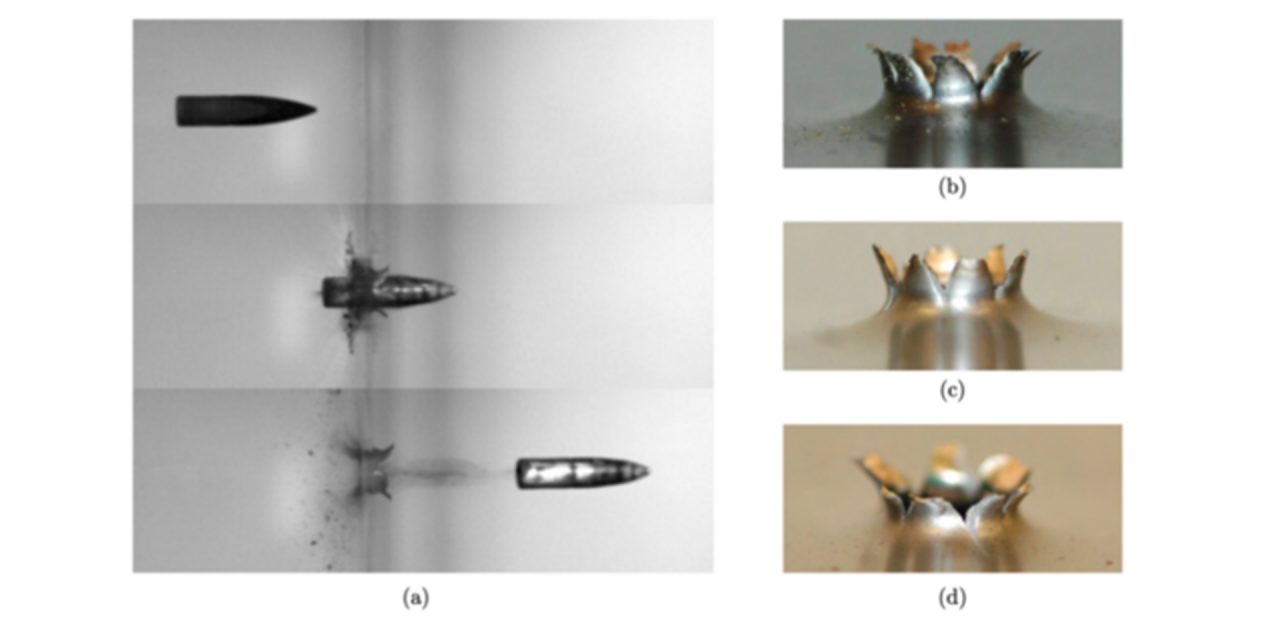

Elveli has compared the behaviour of machined plates with plates hit with real projectiles. Real projectiles created small petal-like cracks and deformation around the points of impact, whereas the pre-formed defects had perfectly even edges.

The explosion tests showed that the destruction started in the cracks and spread outwards. The research thus shows that the simplified approach has weaknesses.

Elvelia advised: “Idealised defects, like in the machined plates, are easier to test and simulate. But because they lack the deformations and damage that occur in real explosions, there’s a risk of exaggerating the strength of the materials in these models.”

Understanding the need to develop accurate computer simulations is clear; researchers who work with strength calculations cannot blow up actual buildings to test their resilience.

Image: Sequence of projectiles being fired through three different steel plates. The pictures on the right show the exit holes in the various plates. © SFI CASA/ SIMLab, Norwegian University of Science and Technology.